The design process of a backpack typically involves several stages, including research, conceptualization, prototyping, and manufacturing. Here is a general overview of the whole design process of a backpack in polyester material:

Research: The first stage of the design process involves researching the target market, trends, and materials. Designers will gather information on consumer preferences, the latest fashion trends, and the most suitable materials for the backpack.

So how to gather information on consumer preferences, the latest fashion trends, and the most suitable materials for the backpack?

- Market research: Conducting market research is a common way to gather information on consumer preferences and trends. This can involve surveys, focus groups, and interviews with potential customers to gather feedback on their preferences and needs.

- Fashion industry publications: Keeping up-to-date with the latest fashion industry publications can provide insights into the latest trends in backpack design. This can include reading fashion magazines, blogs, and social media accounts of influencers in the industry.

- Trade shows and exhibitions: Attending trade shows and exhibitions related to backpacks and fashion can provide designers with ideas and inspiration for their designs. These events often showcase the latest products, materials, and trends in the industry.

- Material suppliers: Speaking with material suppliers can provide designers with information on the latest materials available and their properties. This can help designers choose the most suitable materials for their backpacks.

- Competitor analysis: Studying the designs and features of competitors’ backpacks can provide designers with ideas for their own designs. This can involve analyzing the materials, features, and price points of competing products.

Conceptualization: After the research phase, designers will start to sketch out their ideas and create concept drawings of the backpack. They will consider the overall shape, size, and functionality of the backpack, as well as any unique features they want to incorporate.

How to create concept drawings of the backpack?

- Define the purpose: The first step in creating concept drawings is to define the purpose of the backpack. This may include considering the target market, the intended use of the backpack, and any specific features that the backpack should have.

- Sketch out ideas: Once the purpose of the backpack is defined, sketch out ideas for the design. Start with rough sketches that show the overall shape and size of the backpack, as well as any unique features or details.

- Refine the sketches: After sketching out some initial ideas, refine the sketches to include more detail. Consider the placement of pockets, zippers, and straps, as well as the materials and colors that will be used.

- Create a 3D model: Once the sketches are refined, create a 3D model of the backpack. This can be done using design software or by hand. The 3D model will allow you to see the backpack from different angles and make any necessary adjustments to the design.

- Test the design: After creating the 3D model, test the design to ensure that it meets the design requirements. This may involve checking the weight distribution, comfort level, and functionality of the backpack.

- Make adjustments: Based on the results of testing the design, make any necessary adjustments to the concept drawings. This may involve tweaking the shape or size of the backpack, adjusting the placement of pockets and zippers, or changing the materials used.

Prototyping: Once the concept drawings are finalized, designers will create a prototype of the backpack. This will involve creating a 3D model of the backpack using computer-aided design (CAD) software or by hand. The prototype will be used to test the design, make any necessary adjustments, and ensure that the backpack is comfortable and functional.

How to create a prototype of the backpack?

- Design the backpack: The first step in creating a backpack prototype is to design the backpack using design software or sketching by hand. The design should include all the necessary features and details of the backpack, such as pockets, zippers, straps, and padding.

- Create a pattern: Once the design is finalized, the designer will create a pattern for the backpack. The pattern will be a detailed plan for cutting and sewing the materials, including the dimensions and shapes of all the pieces.

- Cut and sew the materials: Using the pattern as a guide, the sample room will cut the materials for the backpack, including the fabric, zippers, and straps. Then sew the pieces together, assembling the backpack according to the design.

- Test the prototype: After the backpack is assembled, the designer will test the prototype to ensure that it meets the design requirements. This may involve testing the durability of the materials, the weight distribution of the backpack, and the overall functionality of the backpack.

- Make adjustments: Based on the results of testing the prototype, the designer may need to make adjustments to the design or materials. This may involve making changes to the pattern or re-sewing certain parts of the backpack.

- Create a final prototype: Once the adjustments have been made, the designer will create a final prototype of the backpack. This prototype should be a fully functional and accurate representation of the final product.

If you work with Tacole, above steps will be handled by us, so you and your designer just need to check the sample and confirm if it is ok for mass production.

Testing and Evaluation: After the prototype is created, it will be tested and evaluated to ensure that it meets the design requirements. This may involve testing the durability of the materials, the weight distribution of the backpack, and the overall functionality of the backpack.

How to test and evaluate backpack sample to ensure that it meets the design requirements?

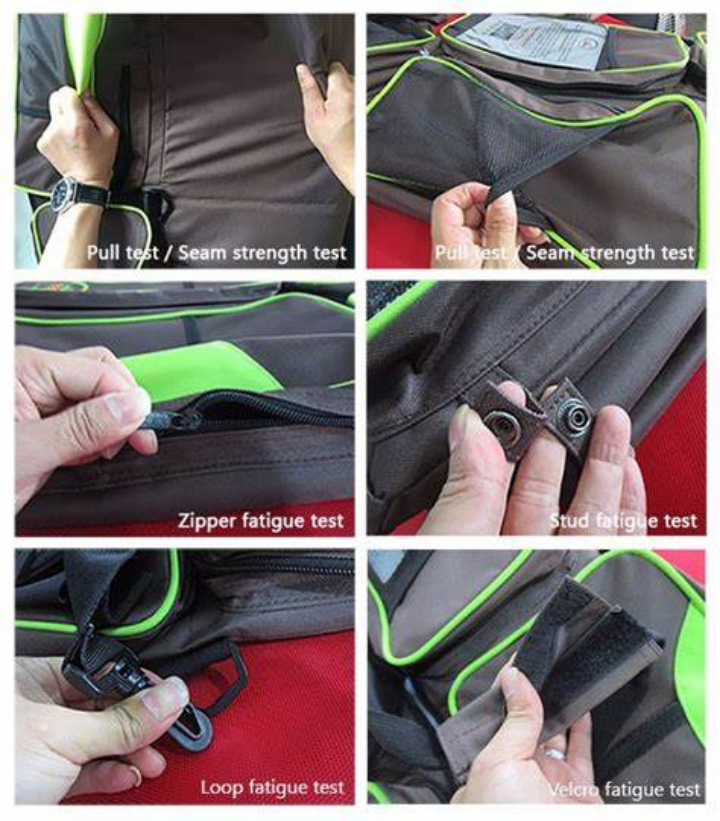

- Test the durability of the materials and zipper:

- One of the most important aspects of a backpack is its durability. To test the durability of the materials, you can apply pressure to the seams and zippers, pull on the straps, and check for any signs of wear and tear.

- Check the weight distribution:

- The weight distribution of a backpack is critical for ensuring that it is comfortable to wear. When testing the backpack sample, make sure that the weight is evenly distributed and that there is no excess pressure on any one part of the backpack.

- Test the functionality:

- The functionality of the backpack is another essential aspect to test. Check that all the zippers, pockets, and compartments work correctly, and that the backpack is easy to open and close.

- Evaluate the comfort level:

- The comfort level of the backpack is crucial for ensuring that it is comfortable to wear. Check the padding on the straps and back panel to make sure that it is comfortable and supportive.

- Test for water resistance:

- If the backpack is designed to be water-resistant, test this feature by spraying the backpack with water or immersing it in water.

- Check the overall quality:

- Finally, check the overall quality of the backpack, including the stitching, finishing, and any other details. Make sure that the backpack meets the design requirements and is of high quality.

By following these steps, we can test and evaluate the backpack sample to ensure that it meets the design requirements. If any issues are identified, you can make the necessary adjustments to improve the design and functionality of the backpack.

Manufacturing: Once the design is finalized and tested, the backpack can be manufactured. This will involve selecting the appropriate materials, cutting and stitching the fabric, and assembling the backpack.

The process of mass production will be as following:

- Purchasing the materials: The first step in manufacturing a backpack is to purchasing materials according to final sample. This may include the fabric, zippers, straps, and other hardware.

- Cut the fabric: Once the materials are selected, the fabric is cut into the necessary pieces using a pattern. The pattern will be used to ensure that each piece is cut to the correct size and shape.

- Sew the fabric: After the fabric is cut, the pieces are sewn together using a sewing machine or by hand. The straps, zippers, and other hardware and details, such as logos, labels, or pockets are also added during this process.

- Thread trimmed: thread end will be trimmed after product is finished.

- FQC and Packaging : Once the backpack is FQC approved, it will be packaged and stored in warehouse as RTS goods.

Quality Control: Before the backpack is released for sale, it will go through a quality control process to ensure that it meets the required standards. This will involve inspecting the backpack for any defects or flaws and making any necessary adjustments.

Click this link to see how inspection will be proceeded.

In summary, the design process of a backpack involves several stages, including research, conceptualization, prototyping, testing and evaluation, manufacturing, and quality control. Designers must consider the target market, trends, and materials to create a functional and stylish backpack that meets the needs of consumers.

One Response