Screen printing is widely utilized because of its affordability and wide range of color options. It is a popular method for private labeling. However, there are very few practical explanations of what screen printing actually is. Therefore, in today’s article, I will focus on the following four aspects:

- What is Screen Printing?

- How much does Screen Printing cost?

- Pros and Cons of Screen Printing

- Screen Printing Basics & Materials: Screen, Squeegee, 3 Common Inks

I believe that after reading this article, you will have a better understanding of screen printing techniques. You can access related content through the provided links.

What is Screen Printing?

Screen printing, as defined by Wikipedia, is a printing method that involves using a mesh to transfer ink onto a substrate, except in areas that are blocked by a stencil to prevent ink permeation.

In simpler terms, screen printing is a technique used to transfer images onto a product’s surface using a screen, ink, and a squeegee. It is also referred to as silkscreen printing because the early screens were made of silk.

In our daily life, we often see bags or backpacks with screen-printed images, as shown in the picture below. It can improve the fabric look and realize private labeling.

How Much Does Screen Printing Cost?

The cost of screen printing is calculated by adding the plate-making charge and the printing labor charge per piece.

- The plate-making charge typically ranges from $15 to $70. Each color requires a separate plate, so the more colors you print, the more plates need to be made, resulting in higher costs.

- The printing labor fee is approximately $0.03 per piece. The minimum order quantity (MOQ) for screen printing is usually at least 500 pieces per item.

A helpful tip to remember is that the cost of screen printing is influenced by the size of the pattern, the number of colors required, and the quantity to be printed. Ordering larger quantities will generally result in lower prices. Additionally, if you purchase more than $2,000 worth of items, most Chinese factories can provide free screen printing services.

Screen Printing Pros and Cons

Screen printing techniques can be applied to a wide range of objects, with the exception of water and air. There is an interesting comment that states if you want to find the ideal printing method on Earth to achieve your printing goals, it is likely to be screen printing. This is due to several advantageous features.

Advantages of Screen Printing:

1.Wide Applicability and Great Flexibility

- Suitable for simple designs.

- Can be applied to almost all products made from various materials, such as business cards, plastic toys, etc.

- Can be printed on flat, curved, and spherical surfaces of both hard objects like glass and soft objects like fabrics.

- No limit on the size of the printing area, ranging from 3 meters × 4 meters and even larger.

Manual and automated printing methods are used, with manual printing suitable for small-scale prints and automated printing for mass production.

2.Long Lasting and Durable

- Screen printing is resistant to fading caused by temperature or sunlight changes, making it cost-effective for sticker production.

- It is particularly suitable for outdoor advertisements and signs.

3.High Quality and Three-dimensional Effect

- Silkscreen art creates a textured effect with a three-dimensional look and feel.

- The colors are vibrant and bright, even on darker fabrics.

- Each distinct color requires a separate screen, allowing for multi-colored image printing using different screens.

4.Affordable Cost and Ideal for Large Orders

- Screen printing offers convenient plate-making processes and lower prices compared to other printing methods.

- It is easier and more cost-effective for large quantities, especially for custom clothing, as stencils can be used to repeat designs multiple times.

Drawbacks of Screen Printing:

- Not suitable for low-volume printing due to high setup costs.

- Not suitable for multi-colored patterns with high skill requirements, especially gradient color designs.

- Less environmentally friendly due to the pollutants generated by the ink used, as well as the plate-making and cleaning processes.

Screen Printing Basics and Materials Used

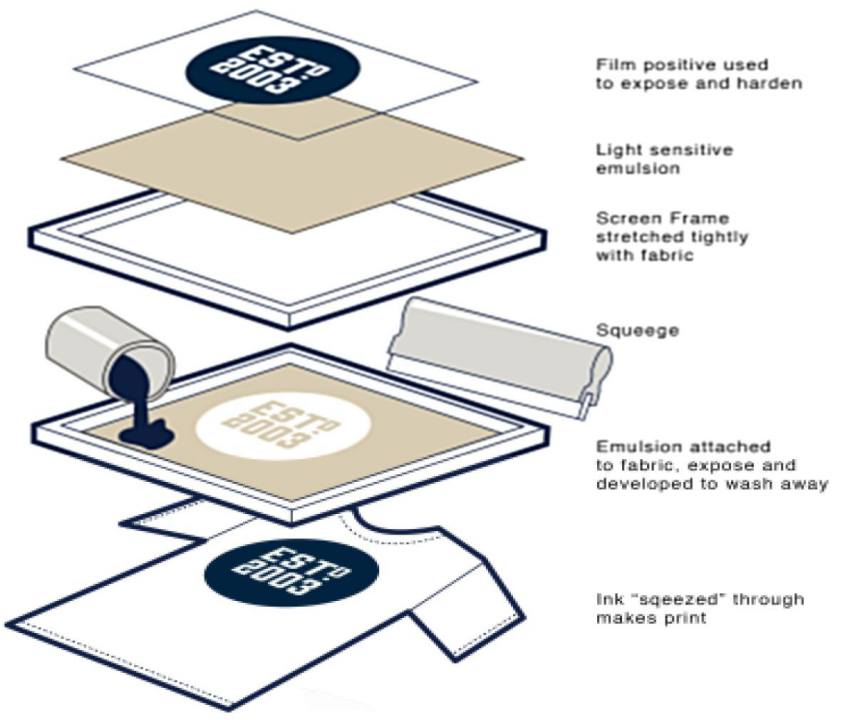

The fundamental principle of screen printing is to push ink through a screen mesh to create the print. The screen printing process can be easily carried out through the following five simple steps:

- Create designs or patterns.

- Prepare the screen plate.

- Apply emulsion and expose it to light to create a stencil.

- Apply ink and print the design onto the product.

- Dry and clean the screen for future use.

The tools and materials used in screen printing mainly include the following:

- Silkscreen and screen plate: These are used to create the stencil and hold the design.

- Squeegee: It is used to push the ink through the screen mesh.

- Ink: The ink is applied to the screen and transferred onto the product.

- Press: The press is used to improve the efficiency of the screen printing process.

- Substrate: This refers to the material on which the pattern is printed. Common substrates include fabric, paper, glass, and plastic.

The Silk Screen and Screen Printing Emulsion

The screen is the most essential component and consists of a metal or wooden frame with a fabric woven mesh. The quality of the fabric directly affects the printing results.

In the early days, silk was used as the mesh fabric. However, polyamide (nylon), polyester, and stainless steel are now widely used as they offer similar performance to silk at a lower cost. High-quality fabrics share the following characteristics:

- High mesh count, indicating a tight weave.

- Resistant to shrinking or reacting with the print paste.

- Able to withstand stress and maintain their shape during use.

- Moisture-resistant and easy to dye.

- Cost-effective.

The screen-printing emulsion is a crucial component as it is applied to the screen to prevent ink from passing through. After coating the emulsion, the screen is exposed to light, creating a stencil. Once the printing process is complete, the screen needs to be cleaned before it can be reused.

The Squeegee

The squeegee is a tool consisting of a rubber blade attached to a handle. It is used to push the ink through the mesh screen and onto the surface below. In manual screen printing, squeegees made from natural or synthetic rubber, such as polyurethane, are commonly used. In automatic screen printing, silicone rubber squeegees are often preferred, with a size similar to the screen frame for better coverage.

Different squeegee firmness or durometer options are available to meet various screen printing needs. The most common durometer range is 75-85. A firmer squeegee is preferred for screen printing fine details in complex patterns. On the other hand, a softer squeegee is needed for relatively simple designs or screen printing on fabrics.

3 Common Types of Screen Printing Inks

3 Common Types of Screen Printing Inks In comparison to the previously mentioned silk screen printing materials, inks are more complex. With numerous types of inks available, it can be confusing to determine which is right for your projects. The choice of ink significantly impacts the printing effect. For example, we often see screen-printed bags that vary in quality, with some looking good and others appearing terrible. This is closely related to the type of ink used. Here, I will list and explain three common types of inks.

A.Plastisol Ink

Plastisol ink is the most common type used in screen printing. It is the preferred choice for the clothing industry due to its good coverage, applicability to most fabrics, and minimal ink waste. However, it has a drawback – a thick feel. Additives can be used to address this issue, but it is less environmentally friendly due to the use of less sustainable ingredients.

B.Water-based Ink

Water-based ink is an eco-friendly alternative to PVC-based plastisol inks. It penetrates the fabric instead of remaining on the surface like plastisol ink. Therefore, it is more suitable for achieving a soft hand feel, which is in high demand in the clothing industry. Additionally, water-based ink offers more detail and longer-lasting prints compared to other types of ink. However, it has limitations in terms of fabric compatibility, as it adheres best to cotton fibers. Bright colors on dark garments require 100% cotton.

C.Discharge Ink

Discharge ink addresses the issue of printing on dark garments by adding an activator that brings the fabric back to its natural color before re-dyeing it. This type of ink stands out for producing bright colors while maintaining a soft hand feel.

Both water-based ink and discharge ink are excellent choices for retail brands that aim to deliver super soft prints. However, it is important to note that there is a higher risk of garment loss with these inks, as the fabric is already dyed and the prints are difficult to fix. On the other hand, small imperfections can be fixed if printed with plastisol inks. Therefore, it is advisable to order a few extra garments to compensate for any defective products.

Final Words

Screen printing has a rich history that dates back 2,000 years ago in China. It was later refined by Japan and further developed in Europe and America. Initially, this technique was kept confidential for industrial use. However, in the 1930s, it emerged as an artistic medium and the term “serigraphy” was coined for its artistic application. By the 1960s, screen printing gained popularity, influenced by artists like Andy Warhol and others.

I hope this blog has provided you with a general understanding of screen printing. If you still have any questions, feel free to leave a message.

At Tacole bags sourcing, we specialize in understanding your needs. As a leading sourcing company in China, we have assisted many clients in building private labeling to their products through screen printing, whether on the product itself or its packaging. If you have any questions or need any assistance, please don’t hesitate to contact us.