You may have come across the terms OEM and ODM in business, but may not fully understand them. These are two significant and widely used collaboration models in the industrial society, particularly in global trade.

This article will clarify the meanings, products, and business models of OEM and ODM using real-life examples, and guide you on how to choose the right OEM and ODM services and suppliers.

1.What’s OEM Meaning in Business Model? (OEM Examples)

OEM stands for Original Equipment Manufacturer. It refers to a company that produces components or products that are sold to other companies who then brand and sell them under their own name.

Examples of OEM Business Model

Automotive OEM: In the automotive industry, OEMs (Original Equipment Manufacturers) are companies that produce vehicles and sell them to other companies who then brand and sell them under their own name. For example, Ford might produce a car that is sold under the Mazda brand. This allows the company to leverage their manufacturing capabilities and expertise to produce vehicles for other brands, while also generating additional revenue.

Electronics OEM: In the electronics industry, OEMs produce components or products that are sold to other companies who then brand and sell them under their own name. For example, a company like Foxconn might produce components for Apple’s iPhone, which are then assembled and sold under the Apple brand. This allows the OEM to leverage their manufacturing capabilities and expertise to produce products for other brands, while also generating additional revenue.

Software OEM: In the software industry, OEMs produce software that is sold to other companies who then integrate it into their own products or services. For example, Microsoft might produce a software component that is integrated into a third-party product, such as a digital camera. This allows the OEM to leverage their software development capabilities and expertise to produce components for other products, while also generating additional revenue.

Overall, OEM business models allow companies to leverage their expertise and capabilities to produce products or components for other brands, while also generating additional revenue. This can be a win-win situation for both the OEM and the brand, as the OEM can focus on their core competencies while the brand can benefit from the OEM’s expertise and capabilities.

However, OEM is not only famous brands are doing, but also commonly used by many small businesses or new brands. Here is other case we had done for one of our customer:

The buyer is from East Asia, and they want us to develop and produce the design of bag for their new brand of travelling bags.

They prepared the design drawing in advance, specifying specific parameters of the product, like length, width, diameter, material selection, the logo, etc.

What they wanted us to help them was just to find a reliable factory with a competitive price, help them follow up the production, arrange inspection and shipment.

2.What’s ODM Meaning in Business Model? (ODM Examples)

ODM Meaning

ODM stands for Original Design Manufacturer, which is a business model where the brand company does not need to design or conduct research and development. Instead, the factory takes care of the entire process from design to maintenance and offers a range of existing product styles for the brand company to choose from. Essentially, an ODM manufacturer produces a product that is then chosen by other companies who request the manufacturer to produce it with their brand name or with slight design modifications. This process is similar to ordering a T-shirt, where the staff provides several styles to choose from and the customer can make changes to the material and decorations.

Examples of ODM Business Model

Small businesses that opt for ODM manufacturing often lack the ability to conduct research and development. Instead, they purchase existing products from China and make minor modifications to the accessories or other aspects before adding their own logo and selling them. For simple items, customization can be as easy as communicating your requirements to the factory.

For example, one of our customers wanted to buy laptop sleeves from China, but was dissatisfied with the existing product styles. They requested the factory to do some modification, and made with their private label. Such products with private labels are called ODM products.

3.What’s OBM Meaning?

OBM stands for original brand manufacturer, which means that foundries create their own private brands and use them to sell their products on the market. This business model covers everything from design and procurement to production and sales. However, it requires a significant investment in building a marketing system, making it more expensive than OEM and ODM businesses. This can also create conflicts with their own OEM and ODM customers. As a result, fewer foundries are interested in pursuing OBM business. Many manufacturers on Alibaba provide OEM or ODM products and services, but most of these products are not sold under the factory’s brand name. This is because they can benefit more from providing ODM and OEM products directly to their customers than investing in marketing their own brands. However, some large ODM or OEM companies do both businesses at the same time.

4.What’s the Difference between OEM and ODM?

What’s the Process of OEM and ODM Services?

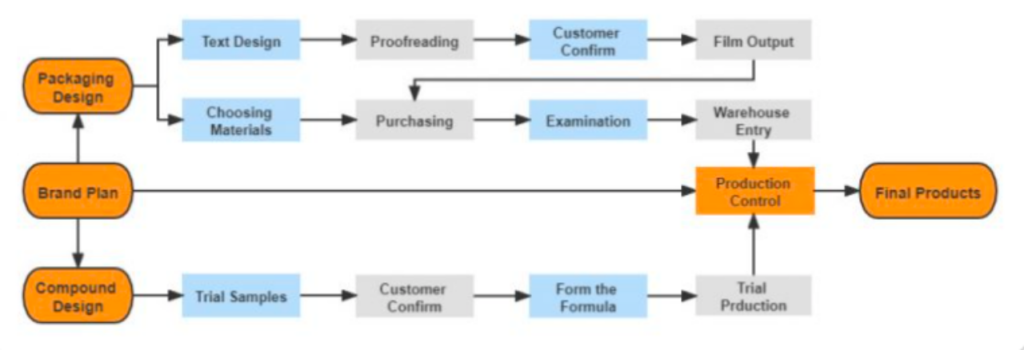

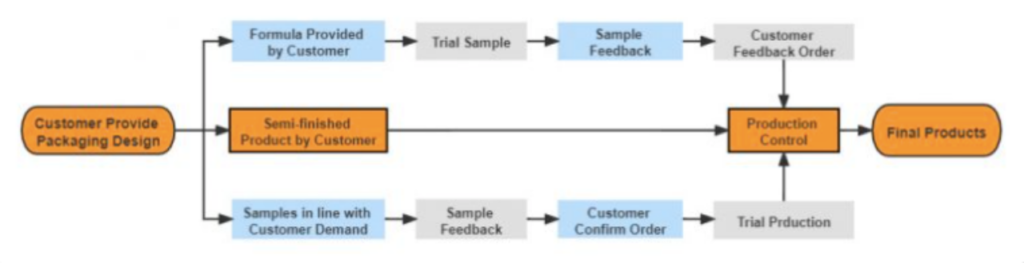

According to the process of ODM product above, I conclude shortly the whole process of ODM service as well as OEM service as the following charts shows:

From the charts, you can find that ODM manufacturing has more process steps than OEM manufacturing. The differences between ODM and OEM manufacturing processes are as follows:

For manufacturers

- Involved in all aspects of products in ODM manufacturing

- While only involved in production in OEM products

For customers

- Provide all necessary information and materials to manufacturers in OEM manufacturing

- While involved less in ODM products, just making decisions in the final steps

5.What are the Pros and Cons of OEM and ODM?

| Compared Differences | OEM Manufacturing | ODM Manufacturing |

| Product Design | Provided by Customer | Provided by Manufacturer |

| Product Patent (IP Ownership) | Belong to Customer | Belong to Manufacturer |

| Product Spec Sheet | Provided by Customer | Provided by Manufacturer |

| Product Unit Price | No Difference | No Difference |

| Investment Fees | More on Product R&D | Mainly on Marketing |

| Production Time | No Difference | No Difference |

| Service Charge | Less | More |

| Product Advantages | Unique Design, Flexible Production | Saving Time to Sell |

| Product Disadvantages | High Costs, Long Product Cycle | Competitive Price, Competition |

Detailed information on OEM and ODM must make you more clear about the two business models. For small businesses, I will list the pros and cons of OEM and ODM for your reference.

Pros of OEM Business Model

Control Product Design

Product design can be fully controlled by customers in the OEM manufacturing model, and the intellectual property of the product also belongs to them. This allows them to choose different manufacturers to produce their products and decide on flexible product designs and standards.

Reduce Production Burden

OEM manufacturing also reduces the production burden for customers, especially large companies, as they only need to pay for materials and processing without having to invest in production equipment or factories. This allows them to place orders according to market demand and make changes as needed.

Form Creative Advantage

Additionally, the OEM model allows customers to focus more on product R&D, which can help them form a competitive advantage through innovation. For example, companies like Apple prioritize product innovation over production methods when selling electronics to consumers.

Cons of OEM Business Model

High Costs, Long Product Cycle

Product design is a resource-intensive process that involves significant investments in R&D, professional knowledge, skills, and ability. These investments also come with potentially high risks, as the design needs to be protected from being copied by other companies.

Additionally, if customers provide their own product design, it can take a long time to prepare and finalize the design before large-scale production can begin. As a result, the entire product cycle for such products is much longer than for ODM products.

Pros of ODM Business Model

Save Time, Save R&D Costs, Short Product Cycle

For small businesses, developing a new product from design to production, such as cosmetics, requires a significant investment of resources. However, choosing the ODM model allows businesses to acquire a product and sell it in a short amount of time. This model also helps customers save on R&D costs, allowing them to focus more on product marketing strategies. For example, with a product like a beer bottle sleeve that already exists, businesses can add some differences and focus on how to sell it rather than designing a completely new product. Additionally, the short product cycle of ODM allows businesses to quickly enter the market with a full range of products while saving time and money on product development.

Cons of ODM Business Model

Highly Competitive, Limited Product Control

In the ODM business approach, it is inevitable to face competition in terms of pricing, variety, and design of products. Lacking a competitive edge in pricing and the presence of similar products in the market can lead to diminished profit margins. For instance, in the case of ring manufacturing, clients opting for ODM services may not enjoy unique design styles or brand advantages in the marketplace.

Since customers do not possess the intellectual property rights for the products, their ability to modify designs or standards is restricted. Their options are confined, and in most instances, they can only determine their satisfaction with the product or the quantity they wish to order.

In conclusion, one might wonder whether OEM or ODM is the superior choice. There is no definitive answer, as the decision depends on individual circumstances. It is advisable for businesses, both large and small, to consider the OEM model if they aim to establish a professional production process that ensures high product quality. On the other hand, the ODM model is more appropriate for companies looking to minimize costs and expedite market entry.

My advice is that the OEM model can help both big or small business guarantee good product quality; while the ODM model is more suitable for those companies who want to save more costs and enter the market quickly.

6.Why and How to Select OEM and ODM Services?

Why Need and Choose OEM Service?

For numerous small enterprises, establishing a manufacturing facility can be expensive and fraught with uncontrollable risks. Additionally, hiring and overseeing a large workforce can be challenging. As a result, many businesses adhere to an unwritten rule: delegate specialized tasks to expert organizations.

For instance, companies that prioritize research and development, such as Samsung, Sony, Google, and Dell, often collaborate with contract manufacturers like Jabil, Wistron, Sanmina, and Celestica to handle production and assembly.

Why Need and Choose ODM Service?

There are two primary scenarios in which ODM services are employed.

Scenario 1:

Companies with extensive sales networks and market expertise may lack research and development capabilities. In such cases, they will seek out a manufacturer with strong R&D skills to create products tailored to their requirements.

Scenario 2:

Some businesses possess R&D capabilities but may find it unprofitable to invest significant time or resources in low-end, low-margin products. In these instances, they typically select an existing product from another company, make minor modifications, and market it under their brand name.

In global commerce, many companies often make minor alterations to existing products for commonplace items like beverage can insulators.

Where to find OEM and ODM Suppliers?

To find OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) suppliers, you can follow these steps:

- Online B2B marketplaces: There are several online B2B marketplaces where you can find OEM and ODM suppliers. Some popular platforms include Alibaba, Global Sources, Made-in-China, and ThomasNet. These platforms allow you to search for suppliers based on product categories, certifications, and location.

- Trade shows and exhibitions: Attending trade shows and exhibitions is another excellent way to find OEM and ODM suppliers. These events provide an opportunity to meet suppliers face-to-face, discuss your requirements, and evaluate their capabilities. Some popular trade shows include the Canton Fair (China), HKTDC Hong Kong Electronics Fair, and CES (USA).

- Industry associations and directories: Many industries have associations or organizations that maintain directories of OEM and ODM suppliers. You can search for these associations online and check their directories to find potential suppliers.

- Networking and referrals: Reach out to your professional network and ask for referrals or recommendations for OEM and ODM suppliers. People in your industry may have experience working with reliable suppliers and can provide valuable insights.

- Social media and online forums: Social media platforms like LinkedIn and industry-specific forums can also be a good source of information on OEM and ODM suppliers. Join relevant groups and participate in discussions to learn about potential suppliers.

- Sourcing agents: In recent years, sourcing agents are popular among importers, especially for new importers. A professional sourcing agent has abundant OEM or ODM factory resources, like us Tacole bags. We can help you select the right manufacturer to make your bag products, negotiate price, follow up production, control quality, inspect products, arrange shipment, etc.

Our thoughtful and comprehensive service will be helpful for your business.

7.How to Identify a Reliable Supplier of OEM and ODM Services and Products?

To ensure a successful partnership with an OEM and ODM supplier, consider these five essential factors when selecting a manufacturer:

- A balance between quality and price

- Effective communication

- A proactive approach to problem-solving

- Comprehensive factory qualifications and certifications

- Clear terms regarding mold ownership and retrieval

Keep in mind that larger factories may not always be the best fit for your needs. Choose a supplier that is attentive to your order and willing to communicate patiently.

The OEM and ODM Product Processes in China

OEM products are designed by customers and produced by manufacturers, while ODM products are both designed and produced by manufacturers. Most products can be offered as either OEM or ODM.

The following are the seven main steps in the OEM and ODM product process, using cosmetics as an example:

Step 1: Develop a prototype or design

The factory will select appropriate cosmetic formulations and create a sample based on your product requirements for testing.

Step 2: Locate a Chinese manufacturer

If satisfied with the sample and price, visit the factory in person to assess their R&D capabilities, production capacity, and facilities. For products with safety concerns, such as cosmetics, it is crucial to partner with reliable and qualified factories.

Step 3: Calculate the project’s overall cost

After visiting the factory, sign a contract and pay a deposit (amounts may vary between factories).

Step 4: Create a pre-production sample

The factory will handle package design and material sourcing, typically at no additional cost. They will create a package design based on your requirements and produce package samples for your selection.

Step 5: Select private label and packaging solutions

Once the cosmetic materials, ingredients, and package design are confirmed, the factory will submit the product for FDA testing and filing.

Step 6: Start mass production

Following testing and filing, the factory will proceed with product filling, packaging, and quality control. This process usually takes 15-20 days. Upon completion, pay the remaining balance.

Step 7: Arrange delivery

The factory will organize shipping, selecting the most suitable method based on delivery time and cargo volume. Cosmetics are typically shipped by sea.

8.FAQs about OEM and ODM

What does Alibaba’s OEM service entail?

As previously mentioned, OEM services are available on B2B online platforms, with Alibaba being a top choice for businesses of all sizes. Numerous Alibaba suppliers and manufacturers offer such products. Additionally, Alibaba features other product services, such as ODM and customization options.

How do ODM and Private Label differ?

There isn’t a definitive line separating ODM and Private Label. Both models involve sellers making modifications to existing products to cater to customer needs and marketing the products under their own brand. In fact, many of our international clients use the terms “ODM” and “Private Label” interchangeably.

How can one initiate OEM or ODM services?

Before opting for OEM or ODM services, it’s crucial to understand your specific needs and the type of products or business models you desire. Regardless of whether you choose OEM or ODM, the shared goal is to reduce production costs and increase profits for a more secure business.

What is the meaning of CM?

Contract manufacturing refers to companies entering into agreements with other manufacturers, who then produce the products while the contracting companies handle sales. This collaboration enhances the utilization of existing resources and streamlines industrial chains, allowing for large-scale and specialized operations.

What does JDM stand for?

JDM signifies joint design manufacture, a model in which manufacturers collaborate with clients to develop products and subsequently introduce these new products to various industries and customers. This approach was pioneered by Chinese server manufacturers, who jointly designed products with major internet companies to secure their position in the internet market.

The End

Thanks for reading, if you have any questions or requests, let me know by leaving a comment below. Or you can consult us about what you want to know about OEM and ODM bag products in China.

We’re Tacole bags sourcing, a leading bags sourcing agent in China. If you want to find OEM & ODM suppliers and manufacturers from China, please feel free to CONTACT US!

One Response

There’s a quiet power in your writing, an ability to convey deep truths without resorting to grandiose statements or complicated jargon. Each sentence feels like a revelation, as if you’ve managed to capture the essence of something fleeting and precious. It’s not often that I find myself thinking about a piece long after I’ve finished reading it, but this is one of those rare times.